Module 2 - Automotive Preventive Maintenance

Our Automotive Preventive Maintenance is designed to equip individuals with comprehensive knowledge and practical skills essential for the pre-delivery inspection, maintenance, and servicing of automotive vehicles. Whether you’re an aspiring automotive technician or an enthusiast looking to delve into the intricacies of vehicle maintenance, this course offers a hands-on learning experience that covers every aspect of automotive care.

Course Outline:

Prepare for Predelivery Inspection

- Identify required items before pre-delivery inspection on the vehicle

- Prepare required items in the vehicle

- Install factory-loaded parts on the vehicle

- Removal of emergency towing eyelets, spring locks, labels, tags, stickers, covers and body

- Protective film

- Adjust tire pressure into standard pressure based on manufacturer’s standard

Perform Physical and Functional Inspection

- Check all electrical components operation in the vehicle

- Check all fluid level in the vehicle

- Check the vehicle for leaks

- Check the vehicle performance

- Check minor defects of the vehicle.

- Accomplish inspection checklist based on manufacturers standards

Complete Work Processes.

- Perform engine oil top-up based on Manufacturer’s standards

- Perform Automatic Transmission oil top-up based on Manufacturer’s standards

- Perform Brake fluid top-up based onManufacturer’s standards

- Perform Coolant oil top-up based on Manufacturer’s standards

Prepare for inspection and service engine

- Determine job requirements from workplace instructions

- Source and interpret servicing information

- Identify hazards associated with the work and manage risks

- Select tools, equipment and materials and check it’s serviceability

Inspect engine

- Carried out inspection according to manufacturer specifications, workplace procedures and safety requirements

- Compared inspection results with manufacturer specifications

- Report inspection findings according to workplace procedures, including recommendations for necessary repairs or adjustments

Service engine

- Carry out service and adjustments according to manufacturer specifications, workplace procedures, and safety and environmental requirements, and without causing damage to components or systems

- Carry out post-service testing according to workplace procedures

Complete work processes

- Make final inspection to ensure work is according to workplace expectations and vehicle or machinery is presented ready for use

- Clean work area, dispose waste and non-recyclable materials and collect recyclable material

- Check tools and equipment and store according to workplace procedures

- Process workplace documentation according to workplace procedures.

Perform pre service preparations

- Determine job requirements

- Source servicing information from service manual

- Use vehicle mileage as reference for changing fluid

- Inspect transmission fluids condition

- Acquire transmission fluids

- Prepare tools for periodic maintenance of drive train

- Manage hazards and risks

Conduct periodic maintenance of drive trains

- Drain fluids

- Replace fluids

- Clean drain plug

- Replace drain plug washers

- Lubricate propeller shafts

- Inspect cracks and leaks of drive train components

- Report findings to immediate superior

- Apply safety practices

Perform post service activities

- Confirm fluid level

- Dispose wastes

- Perform final inspection

- Write down job done

- Restore workplace

Prepare for periodic maintenance of brake system

- Demonstrate Job requirements are determined based on brake system repair order

- Explain the service information sourced from the service manual

- Prepare tools based on suspension system repair order

- Explain hazards and risks associated in the workplace are managed following OSHS

- Job and inspection performed is written/noted down on the repair order.

Carry-out periodic maintenance procedures

- Demonstrate inspection of Brake system components according manufacturer’s service workshop manual

- Enumerate brake system components are replaced according manufacturer’s service workshop manual

- Demonstrate cleaning & lubrication of Brake caliper guide pins

- Demonstrate bleeding of brake system according to service workshop manual

- Demonstrate Adjustment of Parking brake lever/pedal travel and cable tension according to service workshop manual

- Demonstrate calibration of Electric parking brake according to service workshop manual

- Explain reports of findings and recommendations to immediate superior following company’s standard procedures

- Apply safety practices

Complete periodic maintenance procedure

- Explain wastes disposal according to good housekeeping practices

Perform Road test following established standard operating procedure - Explain Job done written on the Repair Order

- Workplace is restored according company’s standard procedure

Perform preperiodic maintenance of suspension system

- State the basic function of the suspension system

- Identify the different types of suspension system

- Explain the features of the different types of suspension system

- Identify the tools, equipment and materials required to service suspension system

- Identify the different safety precautions, hazards and risks when servicing suspension system

- Prepare tools, materials and equipment to be used for suspension system service

Apply periodic maintenance procedures

- Explain why tightening torque must be in accordance with the specified torque

- Identify the suspension system fasteners that requires inspection of tightening torque

- Describe how to check suspension system components

- Describe how to use the torque wrench

- Describe how to check tires

- Describe how to check wheels

- Describe how to check wheel bearing

- Describe how to use the vernier caliper

- Describe how to use the dial gauge

- Apply safety practice when conducting suspension system maintenance

- Demonstrate the correct method for handling of torque wrench

- Demonstrate how to use torque when tightening suspension system fasteners

- Demonstrate how to check tires using a vernier caliper

- Demonstrate how to check wheel bearing axial play using a dial gauge

- Demonstrate how to check tire axial run-out

- Write job done on the repair order

Perform work to completion

- Recognize good housekeeping practices (5S)

- Demonstrate the proper storage of torque wrench

- Demonstrate the proper storage of vernier caliper

- Demonstrate the proper storage of dial gauge

- Conduct final inspection on job performed

- Report findings and recommendations to immediate superior

- Perform good housekeeping practices before and after each job

Perform preperiodic maintenance of steering system

- State the basic function of the steering system

- Identify the different types of steering system

- Identify the tools, equipment and materials required to service steering system

- Identify the different safety precautions, hazards and risks when servicing steering system

- Prepare tools, materials and equipment to be used for steering system service

Apply periodic maintenance procedures

- Explain why tightening torque must be in accordance with the specified torque

- Identify the steering system fasteners that requires inspection of tightening torque

- Describe how to check steering system components

- Describe how to use the torque wrench

- Describe how to replace power steering fluid

- Describe how to check if malfunction exist on electric power steering

- Apply safety practice when conducting steering system maintenance

- Demonstrate the correct method for handling of torque wrench

- Demonstrate how to use torque when tightening steering system fasteners

- Demonstrate how to replace power steering fluid

- Demonstrate how to check electric power steering malfunction

- Write job done on the repair order

Perform work to completion

- Recognize good housekeeping practices (5S)

- Demonstrate the proper storage of torque wrench

- Conduct final inspection on job performed

- Report findings and recommendations to immediate superior

- Perform good housekeeping practices before and after each job

Prerequisite:

Completed Module 1: Fundamentals of Automotive Technology

Who Should Enroll:

This course is for individuals who already completed the Fundamentals of Automotive Technology course, as well as those seeking to pursue a career in the automotive industry. Specifically, the course is suitable for:

Aspiring Automotive Technicians: Individuals who aspire to become professional automotive technicians or mechanics will benefit greatly from this course. It provides the foundational knowledge and practical skills necessary to excel in the field of automotive maintenance and inspection.

Automotive Enthusiasts: Whether you’re a hobbyist or an enthusiast with a keen interest in understanding the inner workings of vehicles, this course offers valuable insights into automotive maintenance and inspection. It’s perfect for those who want to enhance their knowledge and skillset in automotive care.

Automotive Professionals Seeking Skill Enhancement: Experienced automotive technicians and professionals looking to expand their skillset and stay updated with the latest industry standards will find this course beneficial. It offers advanced techniques and best practices in automotive maintenance and inspection.

Individuals Interested in Vehicle Ownership and Maintenance: For individuals who want to gain a deeper understanding of vehicle maintenance and ensure the longevity of their own vehicles, this course provides invaluable insights and practical tips for effective vehicle care.

Overall, anyone with a passion for automobiles and a desire to learn about vehicle maintenance and inspection techniques can enroll in this course and benefit from its comprehensive curriculum.

Training Fee:

₱14,500

Start of Class:

WEEKDAY CLASS:

January 13, 2025 | 1:00 to 5:00 PM (MON-FRI)

February 3, 2025 | 8:00 to 12:00 NN (MON-FRI)

WEEKEND CLASS: January 12, 2025 | 8:00 to 12:00 NN (SUNDAY)

Course Duration:

20 Days Training, 4 hrs. per session

Certification:

Upon successful completion of the course, receive a certification recognizing your proficiency in automotive preventive maintenance.

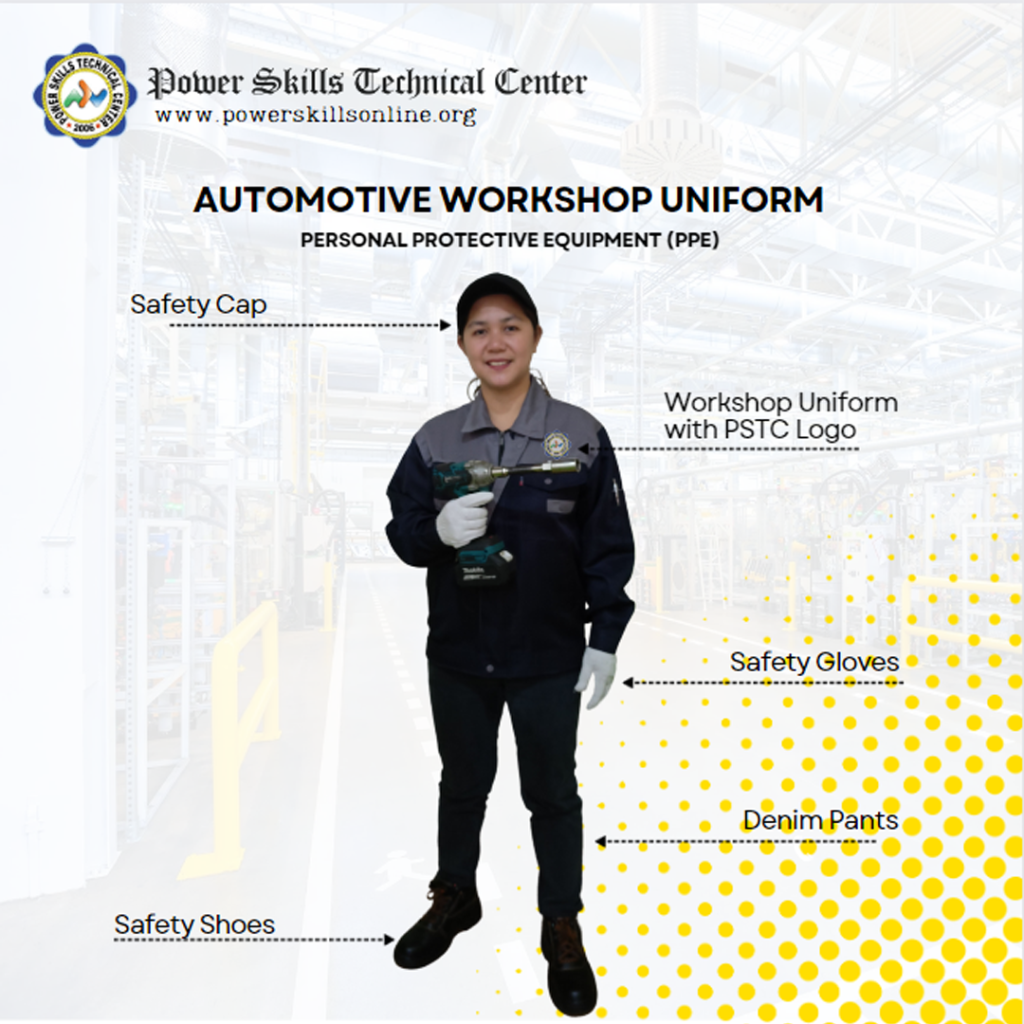

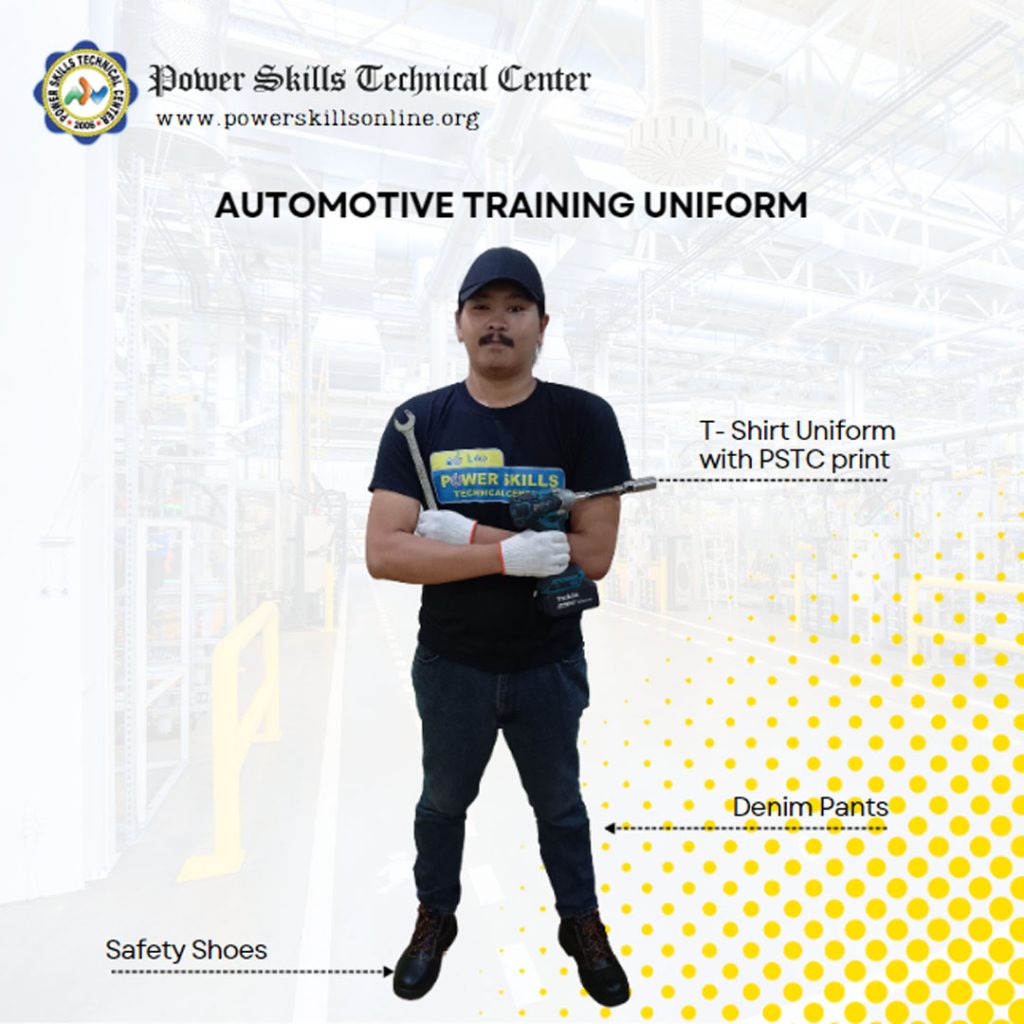

Prescribed Training Uniforms

Here at Power Skills Technical Center, we understand the importance of hands-on experience and professional appearance in the field of automotive servicing. As a part of our commitment to providing a comprehensive learning experience, we require our Automotive Servicing students to have the appropriate uniforms for their practical workshops and training sessions.

Workshop Uniform:

Our workshop uniform is designed to ensure your safety while working in hands-on automotive environments. It includes essential Personal Protective Equipment (PPE) to keep you protected during practical sessions. This uniform is a vital component of your training, as it helps create a safe and productive learning atmosphere.

Training Uniform:

In addition to the workshop uniform, we also provide a dedicated training uniform for your classroom sessions and theory-based learning. This uniform ensures that you present yourself in a professional and focused manner while gaining theoretical knowledge about automotive systems and technologies.

Both uniforms are tailored to meet the specific requirements of our Automotive Servicing program, emphasizing both practical competence and a polished appearance. Wearing the appropriate uniform not only enhances your learning experience but also prepares you for the real-world scenarios you’ll encounter in the automotive industry.

Please note that these uniforms are sold separately from the program fees. To inquire about the pricing and availability of these uniforms, kindly get in touch with our administrative staff. We are here to assist you in ensuring you have the necessary attire to excel in your Automotive Servicing Training program.

GOOD NEWS! EARLY BIRD REGISTRATIONS ARE NOW OPEN!

Unlock Your Future at Power Skills Technical Center with Our Early Bird Promo!

At Power Skills Technical Center, we’re excited to usher in the year with a special opportunity for ambitious learners like you. We’re thrilled to announce our exclusive New Year’s Early Bird Promo for all prospective students looking to kickstart their journey to success.

Regular Training Fee: ₱14,500

However, for those proactive individuals who are ready to kickstart their automotive career journey, we’re offering an exclusive opportunity:

Early Bird Promo Price: ₱12,500

By taking advantage of this limited-time offer, early birds can save as much as ₱2,000 on the training fees. That’s extra value you can put towards your future in the automotive industry.

Don’t miss out on this fantastic chance to secure your spot in our Automotive System Servicing Training program at a reduced rate. Act now, invest in your future, and join us on the road to automotive excellence!

To enroll or learn more about this special offer, please contact our administrative staff today. This opportunity won’t last forever, so seize it while you can. Your automotive career starts here!

Condition:

To avail of the Early Bird Promo, the prospective student must attend the school orientation as announced by the Admin Office. Failure to attend the orientation will result in the tuition fee reverting to the regular rate.